Infrastructure

SOLUTIONS

NanoArchitech provides multi-functional solutions for infrastructure projects with our nanoceramic concrete replacement. Our range of nanoceramic materials offer a synergistic solution to solving climate change challenges such as bridge reinforcement while building back with higher strength and greater resistance to extreme conditions like high force winds and water loads with the benefit of century long life while being eco-friendly sustainable, and a very minimal carbon footprint. Climateskyns and Fireskyns were developed over the years by our inventors who have proprietary IP for a variety of applications based on research collaborations with Argonne National Labs and other scientific research groups.

Fast cure times and an exothermic chemical reaction even in below freezing temperatures is a great advantage to infrastructure work in cold climates.

There is no kilning process in manufacturing , just low and room temperature curing. The challenges we are facing in the built environment if we fail to upgrade construction now will have a negative impact on future generations and results in constant expensive rebuilding with an additional high cost to the environment. Construction accounts for over 40% of global carbon emissions. NanoArchitech intends to have a high impact on this industry saving time, money and emissions.

Bridges & Tunnels

Unlike conventional Portland cement, our rapid-setting & early strength development nano-composites offer a faster and stronger solution while eliminating the high carbon cost of common cement. Nanoarchitech’s materials can be de-molded in 2 hours and achieve the required compressive strength in 24 hours (28x faster than concrete.) Our nanoceramic composite concrete replacements far outlive the concrete they replace. Our materials are highly crack resistant and resist liquid absorption. These attributes help these materials limit corrosion of any internal reinforcing elements. The material’s exothermic cure means it can be used below freezing without changing the mix. It also exhibits minimal shrinkage which further aids large infrastructure projects in many ways. These faster, stronger, long life, and more consistent attributes allow faster rates of construction, reduced costs, safer reopening, as well as greatly reduced traffic congestion time which further reduces carbon emissions.

The material also exhibits low thermal conductivity which would dramatically help to reduce the high thermal mass, urban heat island effect that concrete creates.

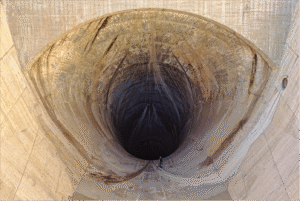

Our nanoceramic materials quick setting, high bond strength, and high early compressive strength assists tunnel infrastructure projects speed, safety, and batch work. The high bond strength also means our nanoceramics materials are able to repair damaged concrete. This reconstruction method has the potential to save billions of dollars and months of time rejuvenating damaged material with high-impact reinforcement and encapsulation.

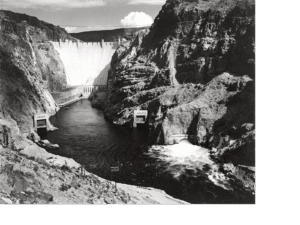

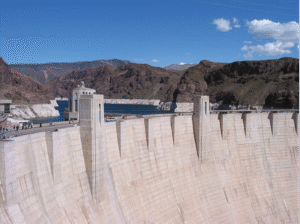

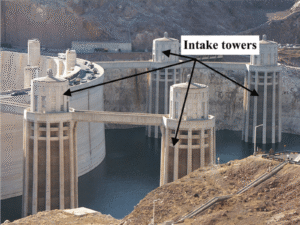

Dams & hydroelectric

hoover-dam-22107954_1920.jpg

Nanoarchitech’s nanoceramics are a great concrete alternative for dams. They have minimal liquid absorption, minimal shrinkage, are extremely crack resistant, have a low thermal expansion rate, and minimal shrinkage as they cure.

A hydroelectric dam by Heidi Smith

Hydroelectric dam & intake towers. Photo by Egor Shitikov by Pixabay

Culverts

Culverts are also an ideal use of Nanoarchitech’s long life, high bonding, & corrosion resistant materials. Our materials high bond strength, extremely fast strength development, and minimal shrinkage allow simpler and safer on site rework as well as infrastructure repairs to help seal out environmental effects on existing structures. Its liquid absorption resistance and crack resistance protect reinforcing elements much better than concrete. Our materials work extremely well in demanding and corrosive environments where concrete does not last.

A worker in a culvert. Photo by Joe from Pixabay

Water treatment facilities

A wastewater treatment facility. Photo by JHenning from Pixabay.

(https://cdn.pixabay.com/photo/2017/10/07/16/27/treatment-plant-wastewater-2826990_1280.jpg)

Our nanoceramic concrete alternatives possess positive attributes for healthier infrastructure. It is antimicrobial which resists bacteria, mold, and fungal elements.

Power

Power plants, generation, and transmission – all ideal use cases of nanoceramics.

Nanoarchitech’s materials exhibit high radiation shielding, a 3000°F temp rating, low thermal conductivity, and a net zero carbon footprint. They are a fantastic choice for power plants, fission, fusion, solar, wind, hydroelectric, power transmission, and substation needs where concrete is typically used. They require no kilning, have an exothermic curing reaction, and have minimal shrinkage as they cure.

Toxin & Radiation Sequestration

A radioactive warning sign from Pixabay.

Our materials offer long life, low liquid absorption, high crack resistance, and high radiation blocking properties. Our nanoceramic radiation shielding is approximately 4x higher than concrete. They are an excellent choice to shield or encapsulate these harmful elements.

Sea Walls, Breakwaters, Piers & Coral Reefs

Our nanoceramic’s low liquid absorption rate along with its low thermal expansion, and high crack resistance means our materials are a perfect choice for harsh environments like piers, sea walls, breakwater features, and man made coral reefs.

A sea wall that illustrates the missing biodiversity you would see on a typical beach. Photo by EdWhiteImages from Pixabay.

Our high bond strength means different features can be added to sea walls to help restore the biodiversity that is typically displaced when a sea wall is added.

Buildings

Utilizing our high-performance, high density thin panel and finish materials have multiple advantages over concrete in the built environment. Rain screens, wall panels, siding, roofing, and many more construction materials made from our nanoceramic composite materials. With it’s fire resistance, low thermal conductivity, low thermal expansion, and 3000°F (1648°C) upper temperature limit, our nanoceramic composites are an excellent choice to help combat climate change and natural disasters.

Concrete crack repair, stamped concrete, concrete resurfacing, and slabs are all places where nanoceramics can replace high carbon concrete.

Concrete Has Evolved

Nanoarchitech evolved from the late John Orava’s work and his companies, Orava Research and Orava Applied Technologies. His lifetime achievement was eliminating the carbon footprint and other negative attributes in typical concrete construction with his nanoceramic alternative. His patents in nanoceramic composites will live on in his award winning materials. We will carry the torch of stewardship and innovation by laying the groundwork of tomorrow. Our climate tech will combat global warming while helping to build back better. Work with us and our powerful, resilient solutions for a brighter future.

2023 – Innovation Fellow Department of Energy IMPEL Accelerator -Lawrence Berkeley National Laboratory LBNL